NYLON AND POLYESTER

Multifilament ropes feel soft when handling.

The basic colour is white. Other colours on request. Both qualities are rot-proof and highly abrasion resistant.

- High abrasion resistance

- Excellent weight/tenacity ratio

- Easy to splice

- Rot-proof

Nylon 3-strand twisted

Nylon 8-strand plaited

Nylon braided

Polyester 3-strand twisted

Construction

3-strand twisted

Diameter/mm marked on each coil – Coils or reels of 100-200-220m

8-strand plaited (torque free)

Circumference/inch marked on each coil

Coils of 100-200-220m

Hawsers: spliced and protected mooring eyes each end

Braided (torque free)

Plastic spools of 100m

Properties

Nylon (Polyamide)

| Relative density | 1,14 | |

| Temperature resistance | Can be used below 0°C Melting point 218°C (Nylon 6) |

|

| UV resistance | Excellent – fully stabilised | |

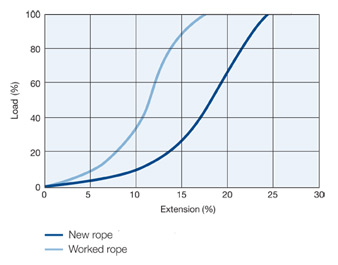

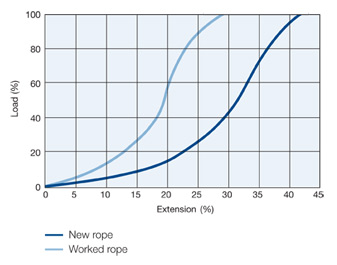

| Extension | Breaking stretch of 35% A lot of energy is stored in the rope – mind the security of people |

|

| Flexibility | Soft and flexible – becomes harder in use | |

| Chemical resistance | Good resistance to alkalis – limited to acids |

Polyester

| Relative density | 1,38 | |

| Temperature resistance | Flexible down to –40°C Melting point 260°C |

|

| UV resistance | Excellent – fully stabilised | |

| Extension | Breaking stretch of 22% wet or dry | |

| Flexibility | Remains flexible – no water absorption | |

| Chemical resistance | Good – except to alkalis |

Length measured under reference tension according to EN ISO 9554

Typical applications

Mooring lines – Deep sea towing – Single point mooring – Tension winch mooring – Mooring ropes for super yachts

Properties

Nylon (Polyamide)

Relative density 1,14

Temperature resistance Can be used below 0°C

Melting point 218°C (Nylon 6)

UV resistance Excellent – fully stabilised

Extension Breaking stretch of 43%

A lot of energy is stored in the rope – mind the security of people

Flexibility Soft and fl exible – becomes harder in use (water uptake ±10%)

Chemical resistance Good resistance to alkalis – limited to acids

Polyester

Relative density 1,38

Temperature resistance Flexible down to –40°C

Melting point 260°C

UV resistance Excellent – fully stabilised

Extension Breaking stretch of ± 24% wet or dry

Flexibility Remains flexible – no water absorption

Chemical resistance Good – except to alkalis

Length measured under reference tension according to EN ISO 9554

Typical applications

Hawsers for ship’s mooring – Towing and mooring springs – General purpose

Nylon and Polyester 3- and 8-strand

| NYLON | POLYESTER | ||||||

|---|---|---|---|---|---|---|---|

| Diam. Ø | Circ. | Mass | Min. breaking load | Mass | Min. breaking load | ||

| mm | inch “ | kg/100m | T | kN | kg/100m | T | kN |

| 6 | – | 2,25 | 0,75 | 7,4 | 2,7 | 0,71 | 7 |

| 8 | 1 | 4 | 1,35 | 13,2 | 4,8 | 1,28 | 12,6 |

| 10 | 1 ¼ | 6,2 | 2,08 | 20,4 | 7,6 | 2 | 19,6 |

| 12 | 1 ½ | 8,9 | 3 | 29,4 | 11 | 2,9 | 28 |

| 14 | 1 ¾ | 12,2 | 4,1 | 40,2 | 14,8 | 4 | 39,2 |

| 16 | 2 | 15,8 | 5,3 | 52 | 19,5 | 5,1 | 50 |

| 18 | 2 ¼ | 20 | 6,7 | 65,7 | 24,5 | 6,8 | 67 |

| 20 | 2 ½ | 24,5 | 8,3 | 81,4 | 30,3 | 8,1 | 79 |

| 22 | 2 ¾ | 30 | 10 | 98 | 36,7 | 9,3 | 91 |

| 24 | 3 | 35,5 | 12 | 118 | 43,7 | 11,8 | 116 |

| 26 | – | 42 | 14 | 137 | 51,2 | 13,9 | 136 |

| 28 | 3 ½ | 48,5 | 15,8 | 155 | 59,4 | 16 | 157 |

| 30 | – | 55,5 | 17,7 | 174 | 68,2 | 17,6 | 173 |

| 32 | 4 | 63 | 20 | 196 | 77,8 | 20,9 | 205 |

| 34 | – | 71 | 22,5 | 221 | 87,9 | 23 | 226 |

| 36 | 4 ½ | 80 | 24,9 | 244 | 98,2 | 27,8 | 273 |

| 38 | – | 89 | 27,4 | 269 | 109,5 | 30,6 | 300 |

| 40 | 5 | 99 | 30 | 294 | 121 | 34,5 | 338 |

| 44 | 5 ½ | 120 | 35 | 351 | 147 | 41 | 402 |

| 48 | 6 | 142 | 42 | 412 | 175 | 47,5 | 466 |

| 52 | 6 ½ | 166 | 48,8 | 479 | 205 | 55,4 | 543 |

| 56 | 7 | 193 | 56 | 549 | 238 | 64,5 | 633 |

| 60 | 7 ½ | 221 | 63,8 | 626 | 273 | 71,7 | 703 |

| 64 | 8 | 252 | 72 | 706 | 311 | 82,7 | 811 |

| 68 | 8 ½ | 284 | 80,1 | 792 | 354 | 94,7 | 929 |

| 72 | 9 | 319 | 90 | 882 | 393 | 107 | 1050 |

| 76 | 9 ½ | 355 | 100 | 979 | 440 | 119 | 1167 |

| 80 | 10 | 394 | 110 | 1078 | 485 | 130 | 1275 |

| 88 | 11 | 477 | 131 | 1284 | 587 | 159 | 1560 |

| 96 | 12 | 568 | 154 | 1510 | 699 | 184 | 1805 |

| 104 | 13 | 666 | 182 | 1786 | 820 | 222 | 2177 |

| 112 | 14 | 772 | 210 | 2061 | 950 | 256 | 2510 |

| 120 | 15 | 887 | 240 | 2355 | 1090 | 290v2844 | |

| 128 | 16 | 1010 | 272 | 2668 | 1240 | 326 | 3197 |

| 136 | 17 | 1140 | 306 | 3002 | 1400 | 367 | 3599 |

| 144 | 18 | 1280 | 344 | 3375 | 1570 | 401 | 3932 |

| 160 | 20 | 1580 | 422 | 4142 | 1940 | 487 | 4776 |

Braided Nylon and Polyester

| NYLON | POLYESTER | |||||

|---|---|---|---|---|---|---|

| Diam. Ø | Mass | Min. breaking load | Mass | Min. breaking load | ||

| mm | kg/100m | T | kN | kg/100m | T | kN |

| 1 | 0,1 | 0,05 | 0,52 | 0,12 | 0,04 | 0,44 |

| 2 | 0,18 | 0,1 | 0,94 | 0,22 | 0,08 | 0,8 |

| 3 | 0,51 | 0,19 | 1,9 | 0,61 | 0,16 | 1,56 |

| 4 | 0,9 | 0,34 | 3,3 | 1,1 | 0,29 | 2,8 |

| 5 | 1,25 | 0,47 | 4,6 | 1,5 | 0,39 | 3,85 |

| 6 | 2 | 0,74 | 7,3 | 2,44 | 0,64 | 6,25 |

| 8 | 3,58 | 1,34 | 13,1 | 4,35 | 1,13 | 11,1 |

| 10 | 5,6 | 2,09 | 20,5 | 6,8 | 1,77 | 17,4 |

| 12 | 8,1 | 3 | 29,2 | 9,8 | 2,5 | 24,7 |

| 14 | 10,5 | 3,9 | 37,8 | 13,3 | 3,4 | 33,5 |

| 16 | 14,3 | 5,2 | 51,5 | 17,4 | 4,5 | 43,9 |

| 18 | 18,1 | 6,5 | 63,4 | 22 | 5,5 | 53,9 |

| 20 | 22,3 | 7,9 | 77,9 | 27,2 | 6,8 | 66,5 |

| 22 | 27 | 9,4 | 91,8 | 32,8 | 8 | 78,1 |

| 24 | 32,2 | 11,2 | 109,5 | 39 | 9,5 | 92,8 |

Load VS Extension Nylon